Last Updated on January 10, 2023

If you have ever sewn with a sewing machine before, chances are that there had been times already when sewing machine tension issues have come up while you’re working on your project.

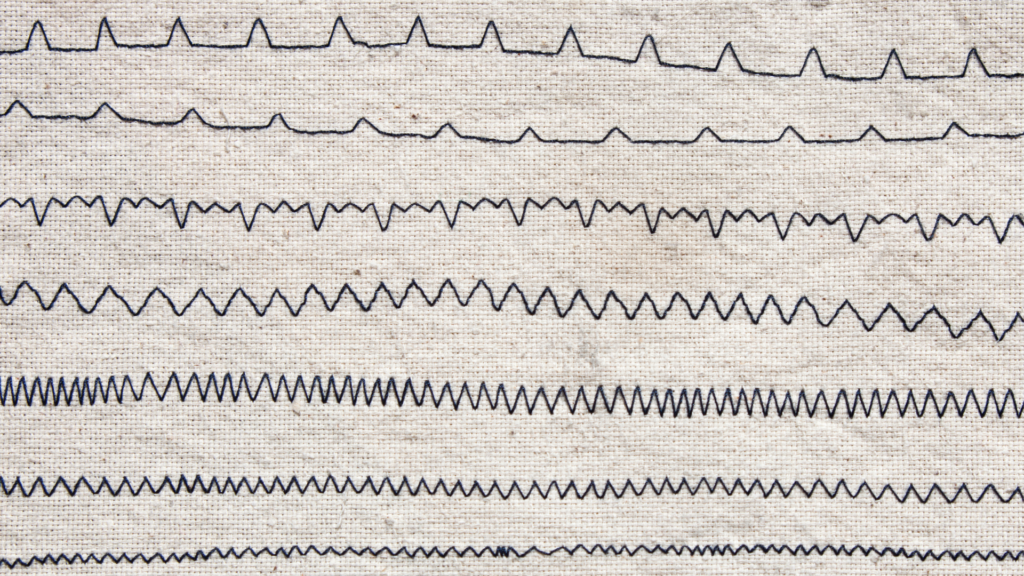

There are many different types of sewing tensions; some common issues are too loose or too tight sewing tension.

Luckily, there are solutions to help fix these problems. In this blog post, we will be talking about some basic (and a bit technical) stuff about sewing machine tension including some sewing machine tension issues.

What is sewing machine tension?

Basically, sewing machine tension is a way to indicate the amount of sewing thread that will be used when sewing. It is typically expressed in a number from 0 to 10, and the higher the number, the tighter tension there would be.

A loose stitch means sewing thread will be more visible and sewing would have a bigger gap. This is because more threads are coming out. On the other hand…

A tight stitch means sewing thread will not show as much and there is less chance of having big gaps in between stitches. This is because less amounts of thread are coming out from the machine at a time.

Tension is determined by the upper and lower parts of the machine. The upper tension is what we’d commonly refer to as the thread tension. Meanwhile, the lower tension is called the bobbin tension. They work in conjunction with one another.

Sewing machine tension plays a vital role when you’re sewing with your machine. It’s often overlooked by beginners.

A sewing machine’s main purpose is to create even, solid stitches in your fabric. The way the sewing machine accomplishes this feat is with its built-in tension.

If there were no tension on a sewing machine then all of the threads would just unravel from one spool onto another which could be disastrous if not caught quickly enough.

New sewing machines have their tension already set when you buy them. However, you will have to adjust it from time to time in order to get the right tension for your project.

How to get the “right” tension

Each fabric has a different weight and sewing machine tension is usually adjusted accordingly.

For example, sewing a lightweight fabric with the same sewing machine tension as for a heavyweight fabric will cause your stitches to be uneven. In short, it will look messy.

This means that as you switch materials in different projects, you’ll need to adjust the tension accordingly.

What we want for our projects is good quality stitching. This is achieved when the tension is “right”.

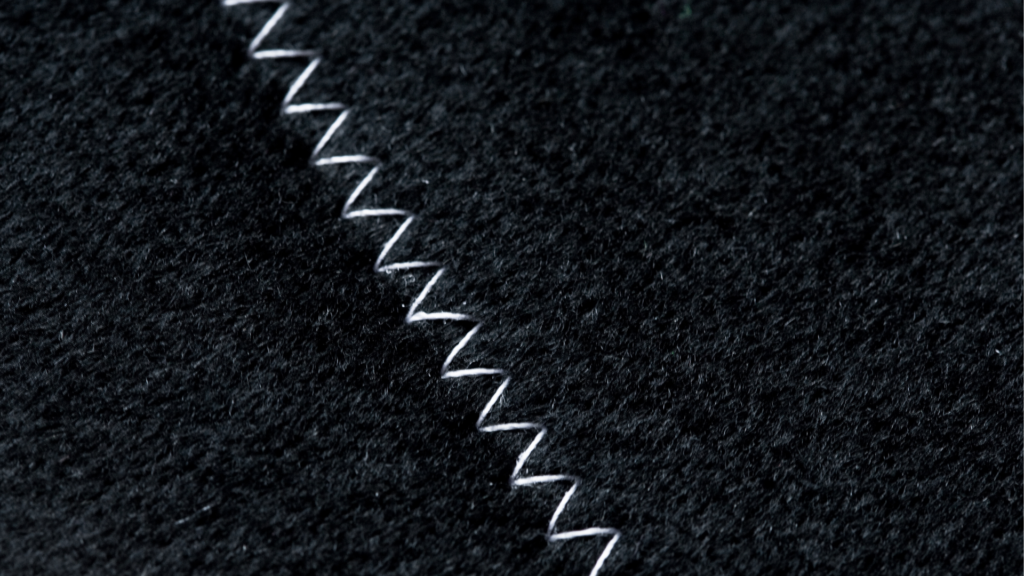

You know that you have a good sewing machine tension when the stitches are even, the fabric is laying flat after sewing, the top and bottom thread are balanced, and that there are no tiny messy loops on either the top or bottom of the fabric.

On the other hand, if you do not see the signs mentioned above, you got to adjust the tension.

A common sewing machine problem that many sewers face is because of incorrect thread tension. Fortunately, we can easily fix this just by adjusting the thread tension.

When adjusting the sewing machine tension, we need to remember the factors that we’re going to look at in this case:

- The thread that is being used (check the type and the thickness)

- The type of fabric that you’re working on

- The stitch type

- The sewing machine needle type and size

Why is my thread bunching up?

Sewing machine tensions also determine how close together the stitches will be on your fabric or garment that you’re sewing.

If there’s too much tension present in the thread on either side of your fabric, the thread will bunch up and create tiny messy loops all over it; this makes for less aesthetically pleasing seams to look at.

If we want our machine to make even stitches with no loops, then both sides (top & bottom) must have equal levels of thread tension across them so that as one increases in pressure, the other one decreases in pressure to match it.

The sewing machine needle type and size are also factors that will determine the level of sewing tension present on both sides of your fabric.

Thinner needles with a smaller eye, for example, can create tighter stitches which means more sewing tension is needed to keep them flat as they pass through layers of fabric.

This may be adjusted by turning up the top stitching dial or back-tacking the thread so that sewing speed slows down enough to hold all those tiny loops together instead of letting them fly out.

However, if you’re sewing thicker fabrics like jeans or denim then we want our stitch length (the distance between each individual stitch) set shorter because thick fabrics require less sewing force from us than thinner materials.

What sewing machine tension should I use?

Usually, you’ll want to use medium or normal tension when sewing most fabrics. This will prevent skipped stitches while still giving your project good stability.

If you’re sewing a delicate fabric like silk, then a low setting may be more appropriate because it’s less likely that these threads will break during sewing — which would lead to messy stitching or damage of the material itself.

Sewing machine tension can be broken down into two categories: differential and constant.

Differential sewing machine tensions are those that the sewing machine automatically decreases when it senses too much pressure on the material, such as an over-threaded bobbin or sewing with a thick fabric.

Constant sewing machine tensions are those which stay at one level of tightness regardless of what type of thread is used or what kind of fabrics you’re working with.

The goal here is to find a balance between these different types so your projects come out looking great without any damage to your materials. Just remember that this will take patience, a good amount of practice, and experience to get right.

How do I adjust my sewing machine tension?

For beginners, we recommend using the dials on either side of your sewing machine as they are self-explanatory.

Sewing machine tension is controlled by a sewing machine’s Tension Control Lever, or the presser foot pressure dial on some sewing machines.

The right amount of tension will depend on your fabric type and stitch length you’re using; experiment to find what works best!

But for those who have been around longer than us know that adjusting this can backfire if you don’t know what you’re doing.

The sewing machine tension is the tightness of your stitches as they come out, and this level must be set high enough to avoid sewing through any thin fabrics like silk or satin but low enough so that heavier seams can also be sewn without ripping them apart.

The sewing machine tension has a direct effect on how well your project comes together in terms of weight distribution, smooth stitching lines, and overall look.

Some Final Words

Sewing is such an enjoyable hobby and a way to relax. But sewing can also be frustrating when it doesn’t go as planned.

The purpose of sewing machine tension is to help create even stitches on your fabric.

Again, getting it right every time will require you to be patient and do some experiments so you’ll learn by experience what needs to be done in certain projects.

We hope that this blog helped you understand the basics of sewing machine tension.

Happy sewing!

![Read more about the article Types of Sewing Machine Threads: Everything You Need to Know [Part 1]](https://www.sewkitkit.com/wp-content/uploads/2021/08/thread-c-300x169.png)

![Read more about the article Types of Sewing Machine Threads: Everything You Need to Know [Part 2]](https://www.sewkitkit.com/wp-content/uploads/2021/08/thread-d-300x169.png)